Military organizations around the world have been working on the seemingly impossible task of reducing the size and weight of soldiers’ equipment while simultaneously increasing functionality and power. For engineers dealing with connectivity issues, this means smaller and smaller connectors, cables and devices. Weight is a particularly vital consideration for the dismounted soldier, who typically carries more than 80 lbs. Given that each soldier wears a backpack, body armor, and carries weaponry and ammunition, finding a desired 20 – 25 per cent reduction in weight requires rethinking the design and packaging of electronic and communications equipment. For instance, night vision, targeting systems, smartphones, GPS, tactical computers and communications equipment could be integrated into a very functional and reliable subsystem, requiring an array of cables, harnesses, and connectors. All of this equipment is necessary, so prime contractors must work with component partners to find ways to lose small amounts of weight in each component so they can achieve a significant weight loss.

Fischer Connectors is taking a radical approach to making that weight loss happen, using its new Fischer Freedom™ Series connector, and working with a variety of vest manufacturers, integrators and sensor manufacturers to reimagine the approach to the tactical vest.

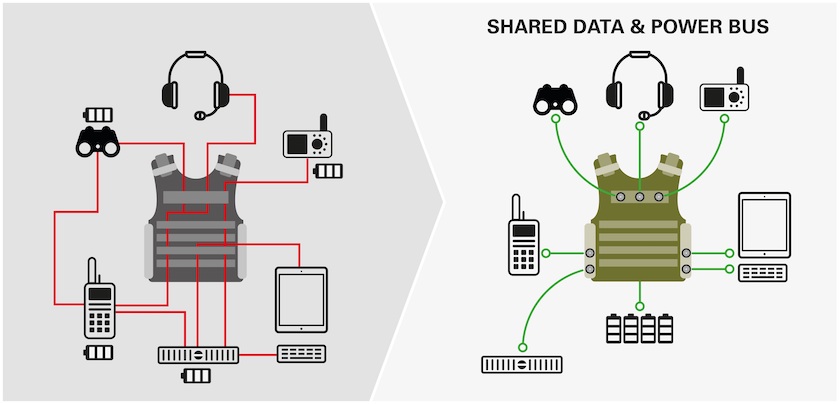

The concept is simple: integrate a distributed data and power bus into the tactical vest, eliminating the need for external wires or break-out cables that currently weigh down the soldier. Receptacles are sewn into the vest and attached into the bus connect to devices and deliver power and signal. A single battery pack powers all the devices. Communications gear, sensors, flashlights, cameras, viewfinders, GPS devices, and other essentials can be attached with matching plugs built directly into the device without the use of cables. It’s part of the overall trend to integrate more wearable technology into military gear, reducing weight and simplifying the use.

In the case of using a wired vest with an integrated bus, the application has two benefits:

- There is a single central source of power, eliminating the need for multiple and different batteries in each of the individual devices. This enables miniaturization, better weight distribution and overall weight savings.

- Integrating the plug directly into accessories and devices reduces the need for external wires that could get caught, pulled or cut in critical moments. This also reduces complexity and increases ease of use and flexibility for the soldier in the field.

Several companies have already started building vests, devices, and sensors based on these concepts, and are testing them in multiple countries.

The wired tactical vest is part of an overall trend toward wearables in defense that is expected to double in the next decade.

The award-winning Fischer Freedom™ Series Connector has seven concentric rings on the receptacle allowing for 360 degree mating freedom. The plug with a sealed membrane protects the contact block with an IP68 rating. Sensors can be built into plugs, or plugs can be engineered directly into devices to eliminate cables entirely. The low-profile plug can also be cabled for communications gear and other devices that do not need to be directly connected to the bus for power or signal.

This new product is a great complement to the Fischer MinMax™ Series, which is designed for signal and power in one small connector, and high-speed data transmission. With these two new product lines, Fischer Connectors has the tools to provide innovative connectivity solutions for tomorrow’s soldiers.

By Wim Vanheertum, Director, Product Management