The sun was shining bright and hot at the 2015 PGA Tour event at Hylands Golf Club in Ottawa, yet if you were standing in one of HDT Global’s tents, you wouldn’t have known it.

Vanguard caught up with Bob Parsons, HDT Global’s Managing Director, to talk about the evolution of the military shelter, and what they’re offering for the Canadian government’s $250 million Headquarters Shelter System (HQSS) project.

The Canadian Forces currently use what you would imagine a military tent to be: heavy, waterproofed canvas over a solid aluminum frame. In fact, that design hasn’t changed much since the 1960s. It’s simple, strong and transports reasonably well.

And while those tents have served our soldiers admirably, they can’t accommodate much for the evolving needs of the military. Technology has marched on, and the Canadian Forces operate differently than they would have a half-century ago.

A testament to the quality of existing shelter designs in use by the military is the fact that they haven’t changed much over the past few decades. But that doesn’t mean they don’t have some drawbacks. The aluminum structure is bulky, which makes it heavy. The canvas is rugged and durable, but also incredibly heavy, and it needs to be laced on to the frame, which takes up a lot of valuable time.

Furthermore, they’re incredibly inefficient to heat or cool. Warm air is pumped in to the bottom and rises to the top of the tent. Cold air stays put at the bottom. The canvas isn’t a good insulator, which means that generators must run longer to power large air-conditioning and heating systems, which also must run longer as the machines work to regulate temperature. All that requires fuel, which, depending on the situation, can be expensive, scarce, or both.

Inefficiencies in one area mean inefficiencies in other, and the government is acutely aware of this, as it all results in increased operating costs. What good is an expeditionary shelter if it is too heavy for a small group of soldiers to carry and set-up? What good are the air conditioners and heaters if they can’t stand up to the harsh conditions the military operates in?

These are all questions that have run through Parsons’ mind; they represent design and engineering challenges that come out of a continuous period of trial and error. And HDT Global’s shelters have been trialed a lot, put through their paces in the Arctic, Afghanistan, Iraq and through dozens of military operations around the world.

The sum of that experience, if you ask Parsons, are shelters that have evolved dramatically from traditional 60s designs. The biggest indicator: HDT’s tents set up in less than five minutes. That’s incredible considering most people need more time to set-up their two-man tent at a campsite.

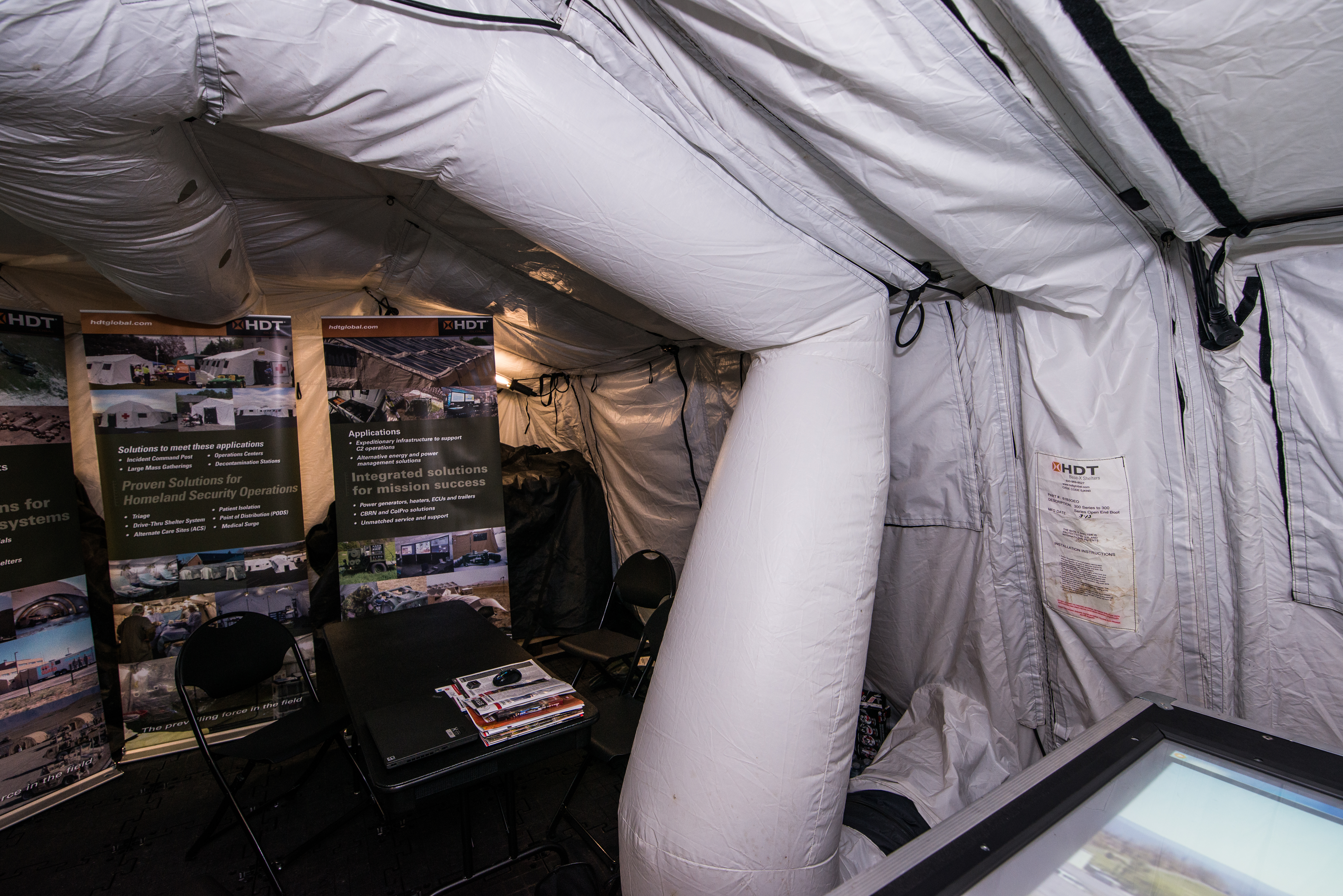

Where soldiers once had to set-up a tent frame and pull the heavy canvas cover over it before lacing it to the structure, now all they need to do is pull, and snap a few aluminum poles in place. The tent comes wired, insulated, and ready to attach itself to other HDT tents via a built-in hallway with a Velcro attachment system. They’re light, transportable, and incredible efficient.

So efficient, in fact, that Parsons claims HDT’s shelters will actually pay for themselves over time. A sliver, bubble-wrap insulation insert placed between the outer fabric layer and the white, inner liner is partially responsible for his assertion. It’s simple science — everyone, especially Canadians — knows the value of insulation, but the challenge for HDT was putting in the capability without making their shelters immobile due to weight.

While that, the HVAC ducting and prewired channels are leaps ahead of the Canadian military’s current stock of shelters, Parsons pays respect to his competitors in the HQSS project, and acknowledges that there are a lot of other capable shelters on offer as well.

Ask him, though, and HDT Global has the advantage of experience, and breadth, behind them. The company’s equipment is built in-house to military standards. They don’t take shortcuts, and HDT’s range of products makes it a “one-stop-shop” for expeditionary forces. Parsons even admits there’s someone at HDT looking into composting systems. Years ago, that would have been unheard of, but soldiers are becoming very conscious of the environment, and the impact that they have on it during operations.

HDT Global appears capable of fulfilling the Canadian Forces’ current (and future) shelter system needs — they’ve already supplied shelter systems to CANSOFCOM — but as everyone in defence knows, nothing is a sure thing. For now, however, Parsons is optimistic. The fact that the shelters are in widespread use by the U.S. military, and forces around the world, speaks for itself.