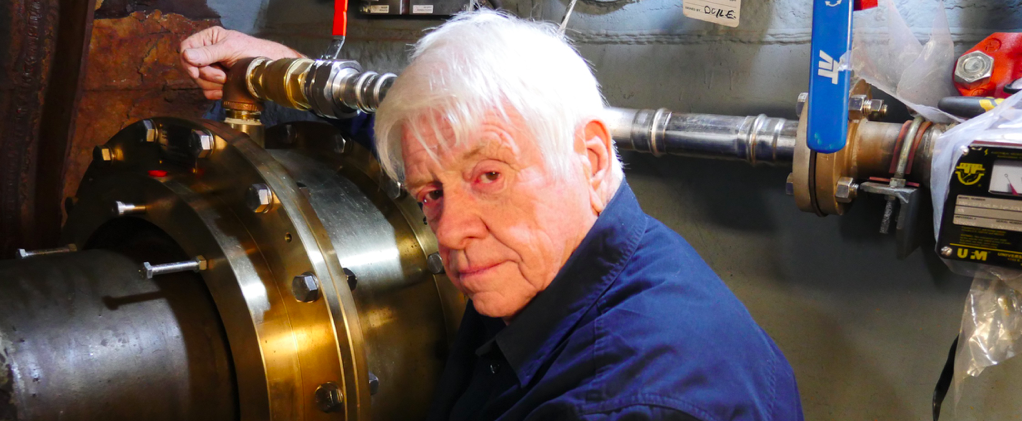

Trained as a pilot and a mechanical engineer, George A. (Sandy) Thomson, the third generation owner of Thomson-Gordon Group Inc., joined his family business in 1965 as sales manager responsible for the development of the Thordon bearing. Two years later he started exporting and distributing the basic shapes from which Thordon bearings were made. Eventually, the distributed products were dropped and focus shifted to bearings and seals for marine and industry.

After his daughter, Anna Galoni joined the family business in 2005 and became the fourth generation owner, Sandy’s role changed. “I’m in the role of innovator,” Thomson said. “After I appointed my daughter Anna as Chair, my assistant suggested this new title. She told me that this is what I do. I guess she is right.”

Here is the full interview with George A. (Sandy) Thomson, Vanguard’s Game Changer for the December/January 2018 issue.

How did you start out in this industry and how has it brought you to where you are today?

I was recruited into the family business from Boston where I had been working. The person behind this move was my mother who was the architect of the event. Since then I was able to blend my passion for music, airplanes, ships with shaft bearings and seals.

What was your worst moment?

The most challenging moment for me was when I needed to put a second mortgage on my home in order to meet payroll. If you’ve been there, you’ll understand.

What was your aha moment or epiphany that you think will resonate most with our reader, tell us that story?

There have been many. In our world of shaft bearings, mechanical seals, lubrication support systems, rudder and deck machinery bearings, advanced aircraft parts, and hydro-turbines, there are always opportunities to make things better. Sometimes it was my idea and other times it was recognizing a good idea offered by an employee, customer, supplier or friend. The key is in recognizing a product idea that could if developed have real merit.

What is the one thing that has you most fired up today?

I want to design and manufacture small hydro-turbines. It’s about renewable energy and the environment and that theme pretty well runs through our entire business. We are now looking at buying a test site on a river in Poland.

What is a habit that contributes to your success?

I got my work ethic from my mother. She lived and died a workaholic. I’m not all that smart but I have always worked hard. I love it. I have figured out how to turn work into pleasure and it’s all about business.

What is the best advice you received?

When I was quite young, my uncle helped me develop the oxidation-reduction equations that allowed me to craft what we called “backyard bombs”. “Billy”, worked on the atomic bomb development. Very secret at the time of course. His advice, ”Make sure the fuse is long enough”.

What people or organizations do you believe best embody the Innovation mindset?

Innovation is a very catchy phrase. These days, it seems everybody is into innovation. I don’t think it’s easy and I don’t think many can do it well. I look for companies that don’t wear it as a badge of honour. They just might be the best ones at it.

How is your organization changing the game within your industry sector?

In our marine business, we are leading the world in mechanical shaft seal designs for water lubricated propeller shafts. In Aviation, we are world leaders in developing a completely grease-free landing gear and flap guide system. This is done through the application of our self-lubricating high-performance polymers.

What are some of the biggest impediments to innovation in your organization or industry sector?

When we deal with government procurement we, unfortunately, encounter a sea of molasses that slows down most and kills others. It’s probably inevitable but still very, very frustrating. When we come upon an enlightened government program like BCIP, it’s like a breath of fresh air.

What are the biggest impediments to innovation in today’s enterprise?

Innovation is not a part of most people’s DNA. It’s alive and flourishing in artists musicians and other creative people, but they are often lacking in manufacturing businesses. We have our own art department that includes a film production business and we produce our own graphic art for marketing. All our marketing is internal and I believe that is very important. We’ve formed a kind of “skunk works” of designers and engineers to develop new product ideas.

What technologies, business models, and trends will drive the biggest changes in your industry over the next two years?

Two years is a short time frame. I see the biggest short-term trend being the increasing adoption of water lubricated propeller shaft bearing systems on new-build ships to eliminate the egregious pollution of the seas by oil leaks from ships. Fortunately, our biggest competitor who is 125 times our size has exactly the same opinion.

What is your parting piece of advice?

To those who think that making money is what it’s all about, I say this. In our companies, we are not in business to make money for the owners. We are in business to make this a better world to live in. Of course, we have to make a profit to grow and survive, but success is much more than making money. Make products that truly save your customer money. Make them to last as long as possible and require the least investment in spare parts.