With each call for proposals, the federal government’s Build in Canada Innovation Program is amassing a remarkable list of Canadian-developed military and security technology. From Mount Pearl in Newfoundland to North Saanich in British Columbia, companies of all sizes have successfully pre-qualified over 150 cutting-edge technologies, many of which are now available for testing with a government department or agency. In this issue, we profile five: one that has been successfully tested and four that have attracted considerable interest from the Canadian Armed Forces.

Visual conversations: Crisis communications goes mobile

We’ve all participated in the video- or teleconference, the one with the fixed start time (sort of), the one where participants connect and then seem to disconnect for no apparent reason, the one where information is displayed (but not everyone can see it).

Video conferencing has been very successful at cost-effectively bringing together dispersed workforces and individuals from multiple departments or agencies. But it’s not how we really communicate with one another, especially in a crisis.

In a world of mobile devices, being able to turn a two-person conversation into a three, four or even 10 person discussion, complete the ability to share various forms of information or stream live video, is invaluable, especially when employees are scattered during an emergency and decisions are required immediately.

In a world of mobile devices, being able to turn a two-person conversation into a three, four or even 10 person discussion, complete the ability to share various forms of information or stream live video, is invaluable, especially when employees are scattered during an emergency and decisions are required immediately.

Ken Davison is chief marketing officer for Magor, a small Ottawa tech firm founded in 2007 by a group of former Newbridge Networks employees, that saw an “opportunity to make video work the way we talk and work.”

“We don’t work to a scheduled environment, we want to be able to hold meetings when we need to,” he observes. And most enterprise videoconferencing approaches were designed around supporting meetings, offering no or limited “ability to support more ad-hoc conversations where people need to bring relevant information in on-the-fly from different sources.”

With Magor’s Aerus Service Delivery Platform, the company has been able to shift from what Davison calls a “presentation model” of video conferencing to a “collaborative model of visual conversations.”

Capitalizing on the rapid growth of smart phones and a potential customer base that recognizes the power of mobility, Aerus allows users to “grow” a conversation organically. What might start as a discussion between one person at an office desk and a colleague on a mobile phone, can easily link in others who might be needed to fill in information or provide a decision.

Data such as PowerPoint slides, photos, video or spreadsheets can be accessed in real-time and shared with specific individuals or the entire group. The type and volume of data can also be scaled up or down depending on the needs of the session (a user can even gauge facial reactions to information by controlling which person to focus on).

The data remains on the host system, meaning that while others can make changes, only the person displaying the data can save them. More importantly, the data is not transferred from device to device, limiting the possibility of passing malware.

Davison says that while many tend to focus on hard returns on investment such as reduced travel, Magor is discovering that the real value is the ability to “reduce or remove of the latency of decision-making.”

Whether it is infrastructure operators or emergency management teams or security professionals with distributed command centres, “all quickly see the value it can bring to decision-making in real time.”

Magor’s technology was accepted by the BCIP during the third call for proposals in early 2012 and was subsequently evaluated by the RCMP.

Unconventional sonar for inaccessible places

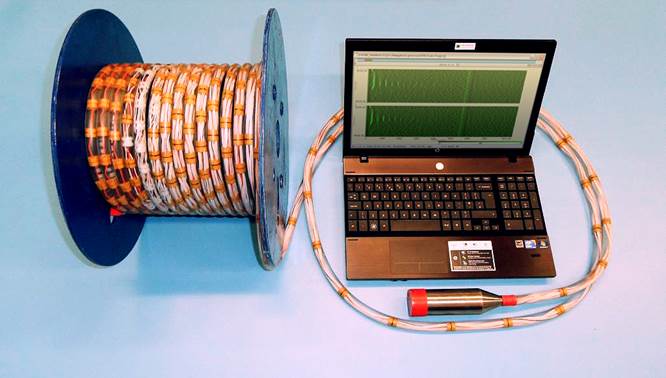

Compared to towed sonars that are usually a 1,000 meters long and weigh several tons, the Universal Acoustic Range and Processor (UARP) by Array Systems Computing is hard to miss with its Ethernet cable-look.

“But that is precisely the point,” says Kris Huber, the North York company’s chief technology officer. “The UARP is designed to be deployed in areas that were previously inaccessible using traditional towed array technology.”

“But that is precisely the point,” says Kris Huber, the North York company’s chief technology officer. “The UARP is designed to be deployed in areas that were previously inaccessible using traditional towed array technology.”

From concept development in 2012, the UARP has become a complete man-portable, low-cost technology to detect surface and subsurface vessels in littoral environments where so-called “blue water” variable depth sonar (VDS) or towed array sonar are unable to operate.

The UARP can be deployed from small ships such as offshore patrol vessels (OPV) or even rigid-hulled inflatable boats, and requires just two to three people to pack, transport and deploy.

Ideal for mobile acoustic surveillance, the technology is an obvious fit for anti-submarine warfare (ASW), especially if installed on an OPV, and would allow a navy to extend its current acoustic detection capabilities. With the rise of coastal diesel-electric and midget submarines now being used to patrol the littorals, the UARP meets a unique need. Conventional towed sonars usually require depths of more than 100 metres and stream to over 1,000 metres behind a vessel. By comparison, the UARP “can operate in 10m of water and stream to 50m-80m behind the vessel,” Huber says.

In shallow, acoustically complex water, the UARP targets frequencies below 1600Hz and has an array gain of approximately 12dB. Based on modeling estimations, and under good conditions, the UARP “can be expected to detect a typical surface vessel on the order of tens of kilometres [away] and a typical submarine a few kilometres [away],” Huber adds.

Most important for navies managing cost, the system does not require large and expensive winches to deploy and recover, so no intrusive upgrades to the ship or to its operating procedures.

The UARP can be used in a bottom-mounted configuration where several sensor arrays can be installed, thus providing wider coverage and the ability to triangulate target positions.

The flexibility of the sonar has garnered Array Systems Computing attention from foreign navies currently investing in their OPV fleets. “We believe our best chances for success are in the export market,” Huber says, acknowledging the company has had detailed discussions with navies in South America and Asia, and in other regions.

But he says Canada could also benefit, especially in the Arctic where more and more international shipping companies are considering the Northwest Passage as a viable route. Coastal and harbour surveillance of surface and subsurface vessels with a low-cost, yet reliable turn-key system would go a long way toward helping Canada assert its sovereignty in this complex environment.

A UAS for ASW and coastal defence

When Brican Technologies first approach National Defence in 2010, it was with a fairly straightforward pitch: an unmanned aerial platform to help locate unexploded ordnance. Brican felt its TD100 (TD for Technological Demonstrator) could assist in locating the more than 5,000 pounds of unexploded ordnance believed to be scattered throughout the bomb range in Goose Bay, where more than six million pounds of explosives have been dropped since 1985 by Canadian and NATO aircraft.

National Defence, however, had other ideas: coastal defence and providing anti-submarine warfare data.

National Defence, however, had other ideas: coastal defence and providing anti-submarine warfare data.

“The real innovation is the system,” says Brican’s president Brian McLuckie. “While most systems are either large or small, we’re kind of in the middle with a lightweight platform capable of flying up to 1,000 kilometres.”

With a nearly five-metre wingspan and a gross weight of 55 pounds, the TD100 is slightly bigger than the ScanEagle, the UAV manufactured by Boeing and Insitu that was deployed by both the Canadian Army and Royal Canadian Navy. Like the ScanEagle, the TD100 is launched autonomously via a pneumatic wedge catapult.

The aircraft will carry CAE magnetic anomaly detection sensors (MAD-XR) as part of its testing process for the anti-submarine detection role. Brican is also exploring variants able to fly well above 20,000 feet and carry as much as 20 pounds, as well as fly for up to 40 hours with a maximum range of 2,000 nautical miles.

While multirole helicopters and medium- to high-altitude UAVs serve a necessary purpose in ASW, all come with a considerably larger price tag than the TD 100. According to data recently released by the Australian Armed Forces, the cost of operating a MRH-90 (which replaced the Australian Sea King) is almost US$12,000 per flight hour while an IAI Heron UAV is about $9,500 and a ScanEagle is $2,700.

There is great potential for mid-sized UAS such as the TD100 for costal defence and ISR, as evidenced by the recent use of the ScanEagle by the French carrier battle group in the Persian Gulf. Brampton-based Brican can also see rising interest in surveillance of critical energy infrastructure, geophysical surveys and wildlife surveys, especially in the High North.

As of April, Brican was still waiting to hear more from the RCAF. In the meantime, the TD100 was selected by the National Research Council of Canada as its “platform of choice” for a program aimed at developing advanced civilian UAVs application. McLuckie said he was hoping that the BCIP will “help attract interested parties within the defence agencies because of the potential [the aircraft] offers Canada.”

Gimme shelter: A blast-resistant solution

At first there were doubts: how could a temporary air shelter provide effective and efficient personnel protection against overhead and ground-launched ballistic threats? “People just did not expect [our shelter] to perform as well as it does,” admits Harold Warner, president of Dynamic Air Shelters, the Newfoundland and Labrador company that builds the Integrated Ballistic Protection System (IBPS).

Dynamic Air Shelters has been manufacturing rapidly deployable temporary air shelters for 14 years, but unlike shelters for first responders or industrial applications, a blast-resistant version offered some unique challenges, starting with “being able to move that much of a sand-filled wall vertically and do that conveniently without excess equipment,” Warner says.

The IBPS shelter has blast resistant doors and the structure recovers quickly from both the shock wave and the debris of an explosion, even from a 5.9 psi blast or 155mm artillery detonated five metres away.

The shelters are available for a range of applications from warehousing, to dining facilities for up to 800 personnel, and can be easily assembled without heavy equipment – operation of winches and a few devices to fill the wall with sand are all the training needed.

The IBPS has already passed a series of successful tests at Canadian Forces Base Suffield and at Tyndal Base in Florida where the U.S. Air Force tested the geo wall both horizontally and vertically.

Although the IBPS has not yet been commercialized, Dynamic Air Shelters has a wide array of customers for its first response, industrial and promotional shelters in Asia, the Middle East, North America and the Caribbean. Warner says that visibility at a tradeshow in 2014 helped the company “complete major transactions in Qatar” and participation in the International Symposium on Military Aspects of Blast and Shock last year furthered its brand.

As of April, IBPS was still waiting for a testing partner under the BCIP, but given the global potential for blast-resistant shelters, Warner doesn’t expect to wait too long.

Augmented reality: Precision in a degraded picture

When your product is already fielded in systems such as the Aegis combat system, the U.S. Army’s Theater High Altitude Air Defense system or the U.S. Navy’s Triton unmanned aerial vehicle ground control station, name recognition shouldn’t be a problem.

Still, Ranald McGillis, president of Ottawa-based Kongsberg Gallium, believes his company is “one of Canada’s best kept secrets in terms of defence technology companies.”

Still, Ranald McGillis, president of Ottawa-based Kongsberg Gallium, believes his company is “one of Canada’s best kept secrets in terms of defence technology companies.”

A leader in geospatial visualization software solutions, Kongsberg Gallium has delivered the operator control software for the Sirius long-range infrared search and track sensor onboard the Halifax-class frigates and has built the mapping engine for the more than 130,000 vehicles that run the U.S Joint Battle Command-Platform software.

With the BCIP, the subsidiary of Norway’s Kongsberg Defense Systems is seeking to highlight the latest version of its InterMAPhics 3D-AR, a commercial off-the-shelf software development toolkit first delivered in the 1990s that has been used in numerous 2D and 3D real-time situational awareness and command and control applications, including air and missile defense systems, unmanned systems, naval C2 systems and land-based systems.

“From desktops to handhelds to embedded processors, we support them all,” says McGillis. “We run on any operating system including Linux, Windows, Android, and differentiate by supporting a plethora of map, imagery and symbology formats.”

Version eight of InterMAPhics was released earlier this year and its augmented reality (AR) application has sparked the interest of the Canadian Army’s Director General Land Equipment Program Management (DGLEPM) and Director Land Command Systems Program Management (DLCSPM).

“AR is essentially the ability to superimpose geo-referenced computer imagery onto an operator’s view of the world,” McGillis explains, and believes the InterMAPhics 3D-AR’s powerful capabilities in three dimensional modelling and three dimensional real-time performance will help address a range of risks associated with degraded visibility due to severe weather, smoke or dust.

While the army’s two directorates will lead testing of InterMAPhics 3D-AR for their own purposes, Kongsberg Gallium says the technology could be applied in combat vehicles, remote operations centres, “and other instances where providing geo-referenced queues will enhance the operator’s effectiveness as the visual picture degrades.”