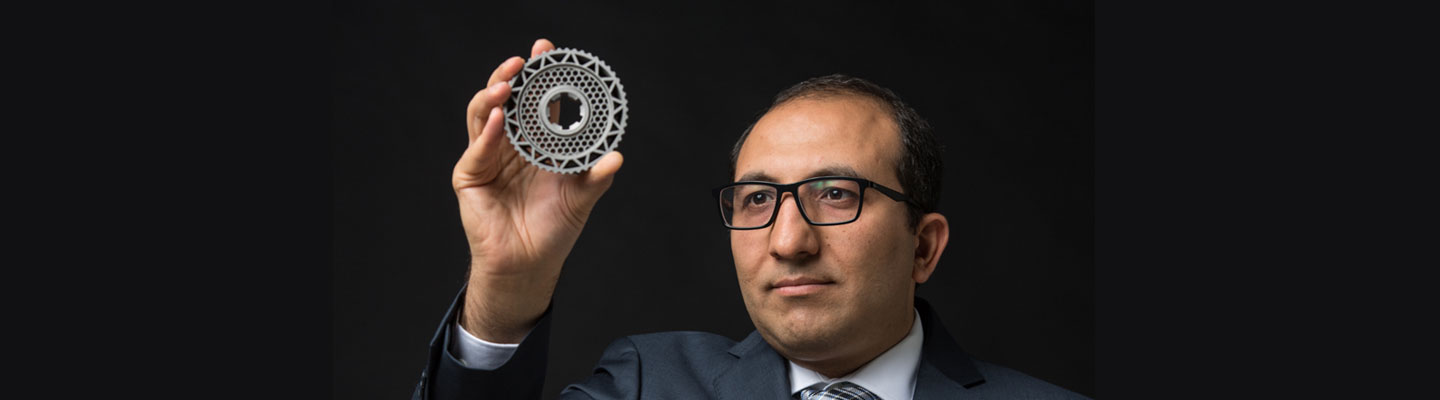

We are excited to announce Vanguard’s latest Game Changer, Dr. Mohsen Mohammadi. As the Assistant Professor of Mechanical Engineering at the University of New Brunswick and also the Director of newly launched Marine Additive Manufacturing Centre of Excellence, Dr. Mohammadi is responsible for training the next generation of engineers, researchers, and designers for the marine sector with the vision to adopt emerging technologies such as Additive Manufacturing, Advanced Materials, and Factory of Future.

“The global marine sector will need more highly qualified personnel both in the naval and energy sections by 2030,” Dr. Mohammadi said. “My role is to help us get there.”

The Marine Additive Manufacturing Centre of Excellence was opened on May 25, 2017, and is the first research centre for 3D printing for the marine and defence industries in Canada.

Here is the full interview with Mohsen Mohammadi.

How did you start out in this industry and how has it brought you to where you are today?

It has all started from a 3-minute pitch session in a university-industry connector event. The office of research services at the University of New Brunswick is very good at arranging these meetings and bringing different industries and researchers together. I pitched the idea of additive manufacturing which opened up the door to be involved in the defence and marine industries.

What was your aha moment or epiphany that you think will resonate most with our reader, tell us that story?

I was looking at how additive manufacturing will shape the advanced manufacturing in coming years in different sectors from aerospace and medical to automotive and energy; and I have found very little regarding the marine sector, specifically shipbuilding, subsea, and offshore energy. That was the moment that I realized that I can make a difference in this field and have a positive effect. I then talked to many colleagues, industrial partners, government researchers, and defence scientists, and realized that this is the place that we can heavily invest in for powder bed and powder fed additive manufacturing research in order to develop new alloys, simplify the supply chain, and keep Canadian marine industries competitive for 2030 marine global trends.

Step back and analyze your journey, what is the takeaway you want to give to our audience?

Be patient, believe in what you want to do, plan ahead, be persistent in your plan, and know that passion and hard work will sell the idea. It is very difficult to introduce a new technology to a sector, which has been around for a very long time like the marine and shipbuilding. But if you have a unique idea, if you have a plan to develop it in this sector, and if you find the right people to buy into your plan, you are there. However, the game will not end there. You have to keep working hard, and have new ideas every day and stick to the plan.

What is the one thing that has you most fired up today?

Recently, I was speaking with a retired colleague from the faculty and he mentioned that he sees this centre bringing a lot of attention not only to the University of New Brunswick but also to the province of New Brunswick. That really fired me up, since I can see that in very near future, we will make a difference and have a positive effect in both education and research and also the economy of this province and the region.

What is the best advice you received?

The devil is in the detail, that was an advice that I’ve received from my PhD supervisor Dr. John Dryden who is currently an Emeritus Professor of Mechanical and Materials Engineering at Western University. Sometimes we have good ideas and can see the big picture, however, we do not have a detailed game plan to reach that goal. We need to have both, brilliant ideas as well as the game plan to get there.

What is a habit that contributes to your success?

There are multiple habits that have contributed to my success. The most important one is persistence. Sometimes people say you have a smart idea, but they do not believe in it. However, when they see that you are persistent, then eventually they will start to believe in it.

What people or organizations do you believe best embody the innovation mindset?

The innovation mindset comes with people who are ready to change anytime they need to, people who can learn new skill sets, people who can steer their ability to fields that they have not tried before. These people can align themselves with the new challenges and regulations. They look at limitations as opportunities to develop innovative solutions. If you have these innovative individuals in your organization with leaders who have a wide vision of the future, then the innovative mindset will evolve.

How is your organization changing the game within your industry sector?

The University of New Brunswick, founded in 1785, is the oldest English-language university in Canada. University of New Brunswick is making a significant difference in New Brunswick and beyond through the creation of knowledge, teaching, and the integration of knowledge into society. The university conducts close to 75 per cent of all research conducted in the province and has put significant efforts, resources, and support to encourage entrepreneurship. This has helped to make a significant difference in the province and nation’s economy.

What are the biggest impediments to innovation in today’s enterprise?

In my opinion, the impediment of innovation in today’s enterprises is simply a group of individuals who does not like to change and adopt new technologies. In the last of couple decades, we have seen big organizations faded away because key decisions that were supposed to be made were not made. It happened both in Canada and overseas. We have to be ready for new challenges. We have to steer the organizations to new endeavors knowing that in the long run, we need to adopt more new things and think with the vision of changing if needed to overcome obstacles.

How has innovation become engrained in your organization’s culture and how is it being optimized?

The Office of Research Services at the University of New Brunswick has led the innovation activities during the last couple of years. This has made University of New Brunswick a “nationwide network of entrepreneurs that celebrates and incentivizes individuals and organizations working to promote entrepreneurship in Canada.” A leading national university, as of fall 2015, University of New Brunswick has over 8,000 undergraduate students, over 1,500 graduate students, over 2,000 faculty and staff across two campuses in Fredericton and Saint John, and more than 65,000 alumni worldwide.

What technologies, business models, and trends will drive the biggest changes in your industry over the next two years?

There are going to be several new technologies for metal additive manufacturing coming to market in next couple of years. These new technologies will significantly decrease the price of a metal 3D printer and will have a significant effect on the technology penetration. Also, industrial grade metal 3D printers will see a price drop due to a bigger competition happening in coming years. We will see more companies trying to practice metal 3D printing and adding it to their supply chain because of the shortage of trained engineers, technicians, and researchers.

What is your parting piece of advice?

Working in the high tech industry is not an easy job. You have to be ready for everyday challenges. Not everybody around you agrees with you, so you have to be able to convince people. You should make sure that you can develop innovative ideas every time you need them. Be yourself and stick to the rules, however, be flexible with new challenges. Right now, Additive Manufacturing and Factory of Future are among the hottest topics in engineering. Be ready for the coming new frameworks and technologies and how to engage with them.